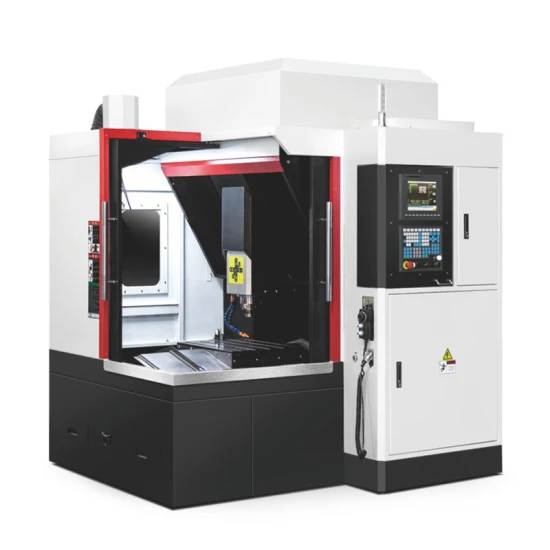

Auto Complementary System Vmc Center 5 Axis CNC Machine Center

Description

Basic Info.

| Model NO. | VMC650 |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Performance Classification | Economical CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Transport Package | Wooden Case |

| Trademark | smac |

| Origin | China |

Packaging & Delivery

Package Size 2700.00cm * 2200.00cm * 2300.00cm Package Gross Weight 5.000kgProduct Description

High-rigidity/high-stability main structure

Use 3D-CAD and finite element analysis to delevlop high-rigidity machine tool structure

Resin bonded sand molding,twice aging,and special tank-type structure and optimized rib-reinforced lay-out,make the machine tool of good rigidity and hysteresis loss

High-speed/high precision three axles feed structure

X.Y.Z three axles all adopt precise linear rolling guide rail(THK or HIWI)

Less noise,low resistance,high speed,high precision

Three axles all adopt C3 degree high precision ball screw,fix the poles of ball screw,fix the poles of ball screw and pre-pull,and optimize drive rigidity,reduce the heat distortion

The poles of ball screw adopt the NSK high-precision angle of contact ball screw bearing

High-speed/high precision spindle

High rigidity,high precision,big hole diameter spindle design,adopyt the precise slide angle ball bearing support

High rotary spindle provides high-speed cutting for customers,ensure the long-term stabilization of machine tool's precision

The spindle adopts synchronous belt drive of big torsion,no friction and less noise

Fast-speed/reliable tool-change system

Can choose 20 bamboo split type or 24 arm press type ATC device,and can rotate the blade cutter very fast,steadily and reliably.

Machine tool cooling system

The machine tool prepares three passes cooling liquid and one pass cooling air nozzle to make cutter cool.

The design of economical and reliable spindle head cooling system(optional),avoid the problem of place error caused by the spindle head temperature raising,ensure the spindle head's working precision,extend the spindle's service life.

Protection and chip system

Close protection design,provide comfortable and safe operation environment,the machine adopts the water and oil separating structure design and have no pollution.

Automatic concentrated lubrication system

Can choose to be equipped with auto chip device and collecting chip car to reduce the operator's labor intensity

High-performance electric control system

Can be equipped with multiple world new brand high-performance CNC controller,digital drive device;meet the requirement of time development in high-speed and high precision

Standard configuration RS232 interface

Have the handy electric operation unit,easy to operate

Fit the CE safety norm and electric box mold-style design,make the electric system easier and reliable

Main control parts all adopt imported new-brand products,have high reliability.

Humanized operation system

Double-open wide protection door for operator to access working table more conveniently

CNC Machine Center(vmc640)

Suitable working table's height for operation

Control plate can rotate 90 degree

Reliable quality assurance

Only after the inspection of three-coordinate measure instrument,each big piece can be assembled.

Every procedure can go into the next procedure for production only after strict inspection

Each machine tool must be inspected by renishaw laser interferometer and ballbar Transducer and also adopts renishaw auto complementary system to compensate for each coordinate axle,make the tack precision achieve its best condition.

Main configurationAutomatic Pump: Herg ,1pcs , Japan

Manual air gun : 1pcs

Manual pulse generator: 1pcs ,from Taiwang

Alarm light in three colors :1pcs

Work lamp :1pcs

Spindle Motor:1pcs,Fanuc

Spindle :1pcs,Posa ,Taiwang

BK3 Coupling: 3pcs,R+W from Germany

Synchronous wheel : 1pcs,Posa, Taiwang

Synchronous belt:1pcs ,Posa,Taiwang

Ball screw: C3 class ,4012,Posa, TAIWANG or THK , JAPAN

3axle Balling (roller)Bearing:6sets/12pcs , NSK , JAPAN

Precision Locked nuts:6pcs

Balance block: 1pcs

Balance chains: 12A -1*79

| Machine Type | VMC650 | |

| Working table | Working table's size mm | 800x420 |

| Working table's maximum bearing capability kg | 400 | |

| T-nuten | 3-18 | |

| Travel | X axle travel mm | 600 |

| Y axle travel mm | 420 | |

| Z axle rtravel mm | 500 | |

| Working table to spindle's face mm | 80-580 | |

| The distance from Spindle's center to vertical guide rail mm | 550 | |

| Spindle | Spindle's rotary speed m/min | 8000 |

| Spindle's specification | BT40-Φ120 BT40-Φ150(optional) | |

| Spindle Motor kw | 5.5/7(Fanuc) | |

| Feed speed | Fast-moving speed m/min | 18 |

| Feed speed m/min | 5 | |

| Feed motor kw | X.Y:1.6 Z:3 | |

| Auto cutter-change device | Tool shank model | MSA BT40 |

| Blind rivet type | MSA P40T-1 | |

| ATC type(optional) | bamboo split 16 cutters | |

| Machine tool's size | Appearance size mm | 2650x2000x2235 |

| Weight T | 4.5 | |

| Drive requirement | Pressed air Mpa | 0.6 |

| Air consumption L/min | 500 | |

| Electric power requirement KVA | 15 |

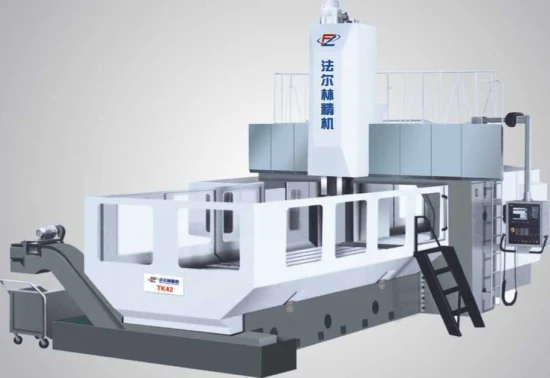

Prev: Fanuc Control Vertical CNC Drilling Tapping Milling Machine Center for Metal Vmc Cx

Next: High Precision Vertical 3 4 5 Axis CNC Milling Machine Tools Milling Center for Metal Working

Our Contact