125 Ton High Precision Servo Hydraulic Punch Press Machine for Metal Hole Punching

Package Size 120.00cm * 110.00cm * 240.00cm Package Gross Weight 6000.000kg 125 ton High Precision Servo Hydraulic Punch

Description

Basic Info.

| Model NO. | YZ-125T |

| Punch Shape | Closed Punch |

| Slider Movement | Single Action |

| Slider Drive Mechanism | Crank Press |

| Controlling Mode | Artificial |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Precision | Normal Precision |

| Certification | ISO 9001 |

| Condition | New |

| Machine Weight | 3700 Kgs |

| Motor | 7.5 Kw |

| Die Set Height | Adjustable |

| Stroke Time | 40 Time/Min |

| Machine Size | 1600X1300X2400 mm |

| Usage | Metal Punching Holes, Bending, Cutting |

| Machine Color | Green, White and Optional |

| Application | Metal Processing |

| Key Word | Punching Machine |

| Product | Hydraulic Punch Press Machine |

| Transport Package | Plywood Case |

| Specification | J21-80T |

| Trademark | ND |

| Origin | China |

| HS Code | 8462490000 |

Packaging & Delivery

Package Size 120.00cm * 110.00cm * 240.00cm Package Gross Weight 6000.000kgProduct Description

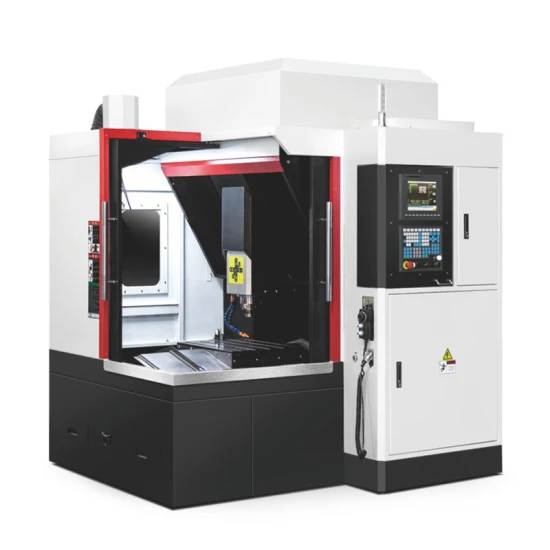

125 ton High Precision Servo Hydraulic Punch Press Machine for Metal Hole Punching1.Hydraulic punching press machine descriptionThe machine is suitable for automatic operations forming, punching, bending, straightening and multi-press assemblies to formautomatic production line.Hydraulic control cartridge valve integrated system is reliability, long-life, small hydraulic impact, reducing connecting pipewith the leak Independent electrical control system, reliable, easy maintenance. Fully enclosed drive, easily accessible formaintenance, exposed over hanging parts, slide and bolster tables with T-slots.Protective fence and the safety interlock ensure the operation safety. Movable single-hand pedal switch makes it easy to operate.Working pressure can be customized from 5T to 500T according to client's requirements.

2.Hydraulic punch press machine details

1. Energy SavingCompared with the traditional hydraulic machine, the energy saving effect is remarkable. According to the processing technology and the production cycle, the servo drive hydraulic machine can save 30%~70% compared with the traditional hydraulic machine. 2. Less Heat, Low CostBecause the pump has zero speed and low heat generation for most of the time, the fuel tank of the servo-controlled hydraulic press can be smaller than the traditional hydraulic press tank, and the oil change time can be extended. Therefore, the hydraulic oil consumed by the servo-driven hydraulic press is generally only about 50% of that of the conventional hydraulic press. 3.High Degree Of AutomationThe pressure, speed and position of the servo-driven hydraulic press are fully closed-loop digital control, with high degree ofautomation and remote automatic control.

3.Hydraulic servo press machine Feature

Computer optimization C - type structure design, good rigidityAll parts of the machine are installed in the fuselage, occupying a small tidy aesthetic appearanceMachine travel, pressure can be adjusted within the specified rangeLift-out or hydraulic pad functionPhotoelectric protective deviceThe holding functionSingle - arm hydraulic press USES hammer - belt motor, low energy consumption, low noise

4.Hydraulic punch press machine parameters

| No | Item | Data |

| 1 | Power | 37.5KW |

| 2 | Bucket capacity | 2.8 M3 |

| 3 | Operating weight | 125Ton |

| 4 | Max. tractive force | 96kN |

| 5 | Max. breakout force | 96kN |

| 6 | Tipping load | 60kN |

| 7 | Engine displacement | 6750ml |

| 8 | Max. torque | 500N.m |

Q1: How can i get the after-service?

A: We provide one year guaranteeWe will send you the spare parts if the problems caused by us.Any problem, you can call us directly.

Q2: Can I have a visit to your factory before the order?

A: Sure, welcome to inspect our factory.Our factory address: No219 Xingye Road Tengzhou City Shandong ProvinceWe can pick you up in the Tengzhou stationHotel booking service is available .

Q3:Are you a factory or trade company?

A: We are manufacturer with own factory , export proportion 50~60%.Q4:How can i trust your company?

A:We have professional design, we can provide you suitable suggestion and lowest price1. Assessed by third party, national patents and CE, ISO for all equipment, .2. Welcome to inspect anytime. 3. Trade Assurance is available.

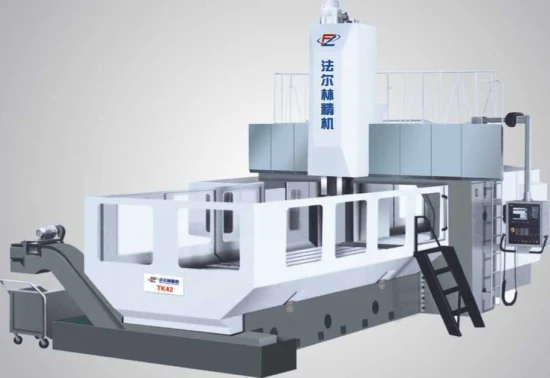

Prev: Vmc1060 China Metal Working CNC Milling Machine Vertical Machining Center

Next: Beiene New Smart CNC Busbar Punching and Cutting/Shearing Machine

Our Contact

Send now