CNC 5 Axis Milling Machine Gantry Type CNC Machining Center

Description

Basic Info.

| Model NO. | Gantry Type cnc machining center |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.04~0.05(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE |

| Condition | New |

| Transport Package | Packing in Seaworthy Wooden Cases |

| Specification | Worktable size: 3000/4000/5000/6000 x 2300 |

| Trademark | DRC |

| Origin | China |

| Production Capacity | 500 |

Product Description

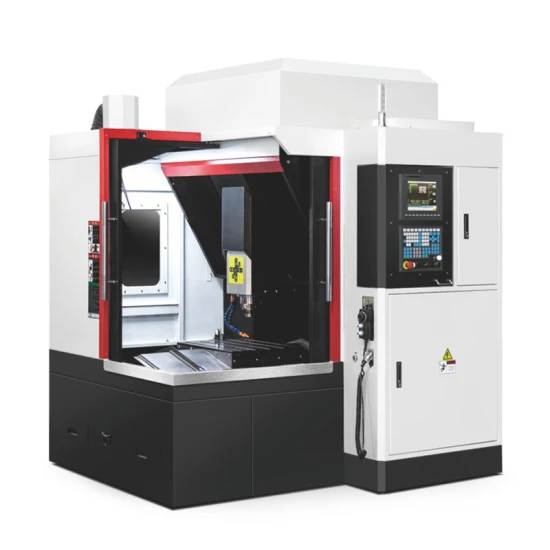

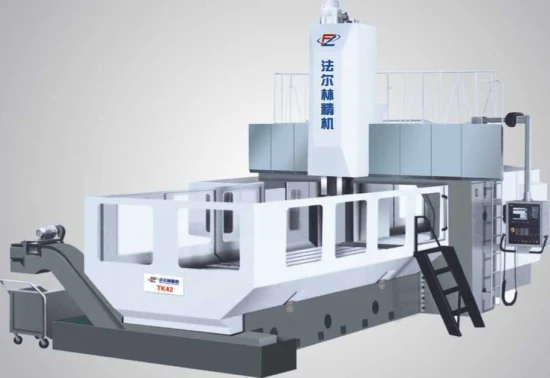

cnc 5 axis milling machine Gantry Type cnc machining center

Latest New Design Factory Price Taiwan Accessories Machining Center China Mini Cnc Router Gantry milling Lathe Machine

Widely used in the aviation, auto, precision molding industries. GMC series can provide a high-performance mechanical system and a software interface which can be operated easily. This provides multiple choices of multiple choices that will allow you to fully realize the high precision dream.

| Specifications | 32B Series | ||||

| Machine Type | Unit | GMC3032B | GMC4032 B | GMC5032 B | GMC6032 B |

| Worktable | |||||

| Worktable (length×width) | mm | 3000×2300 | 4000×2300 | 5000×2300 | 6000×2300 |

| Maximun Load of table | kg | 15000 | 18000 | 22000 | 25000 |

| T-slot | mm | 11-22×200 | |||

| Triaxial itinerary | |||||

| Gantry width | mm | 3230 | |||

| Travel for X/Y/Z axis | mm | 3200/3200/1000 | 4200/3200/1000 | 5200/3200/1000 | 6200/3200/1000 |

| Distance from spindle nose to table surface | mm | 310-1310 | |||

| Feed system | |||||

| CNC system | FANUC Oi MD | ||||

| Rapid shift of axis of X/Y/Z | m/min | 12/12/10 | 10/12/10 | 8/12/10 | |

| Maximun cutting feed speed | m/min | 7 | |||

| Automatic tool transform system | |||||

| Standard tool quantity | Piece | BT50/32 | |||

| The larges diameter cutter knife/length | mm | Φ125/300 | |||

| Tool exchanging manner | Pneumatic | ||||

| Maximum tool weight | kg | 18 | |||

| Precision | |||||

| Positioning accuracy | mm | 0.021 | |||

| Accuracy of repeated | mm | 0.02 | |||

| Guide form and specifications | |||||

| X/Y/Z-axis guide specifications | 3-55(X)/2-55(Y)/Z axis hard rail | ||||

| Spindle system | |||||

| Spindle specifications | BT50/Φ200 | ||||

| Speed with belt drive milling head | r.p.m | 4000 | |||

| Motor power of spindle | kw | 22/26 | |||

| Air pressure | |||||

| Requirements for air | kg/cm² | ≥6 | |||

| Air pressure flux | m³/min | ≥0.5 | |||

| Machine specifications | |||||

| Integrated weight | kg | 45000 | 50000 | 54000 | 56000 |

| Overall dimension (length×width×height) | mm | 7840×5750 ×5167(Travel peak) | 9840×5750 ×5167 (Travel peak) | 11840×5750 ×5167 (Travel peak) | 13840×5750 ×5167 (Travel peak) |

StructureThe structure of machine tool is analyzed with ANSYS at all stages from foundation design to guarantee of high-speed and high-precision continuous machining. A simulation test for deformation produced when the center of machine tool bears load is conducted to guarantee excellent bending rigidity of machine tool.

Our Contact