Cutting Pipe Threads on Automatic CNC Lathe Machine

Cutting Pipe Threads on Automatic CNC Lathe Machine Standard configuration 1.CNC system :GSK, 2.The spindle servo speed,

Description

Basic Info.

| Model NO. | CQK350 |

| Performance Classification | High-End CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| CNC Controller | GSK, Siemens, Fanuc |

| Tool Bar Section | 40X40mm |

| Servo Motor | 18kw,33.3Hz |

| Distace Between Double′s Chuck End | 1790mm |

| Process Pipe out Diameter | 114-350mm |

| Spindle Bore | 355mm |

| Spindle Speed | 7.7~198.9 Rpm |

| Motor Power | 15kw |

| Max Swim Over Bed Diameter | 1000mm |

| Transport Package | Wooden Case with Iron Foot |

| Specification | 6mx2.3x2.2 |

| Trademark | Taian Yuzhuo |

| Origin | China |

| HS Code | 8458110090 |

| Production Capacity | 400set/Year |

Product Description

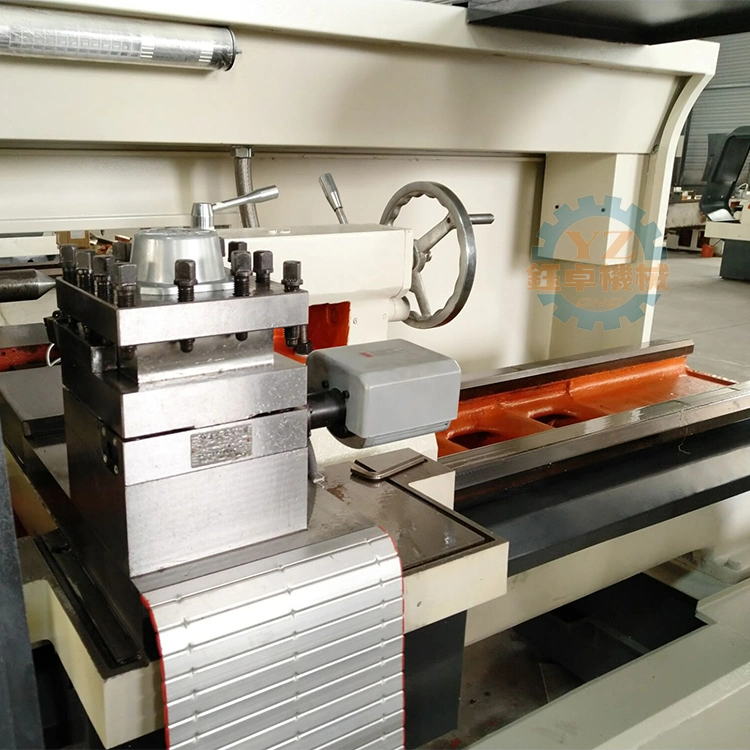

Cutting Pipe Threads on Automatic CNC Lathe Machine| Item | Unit | CK1335 | CK1343 |

| Max dia. swing over bed | mm | 1000 | 1000 |

| Max dia. swing over cross slide | mm | 610 | 610 |

| Max length of workpiece | mm | 1500 | 1500 |

| Width of bed | mm | 755 | 755 |

| Spindle bore | mm | 360 | 440 |

| Power of spindle motor | Kw | 22 | 22 |

| Mode of spindle speed | Two gearsSmooth adjustment | Two gearsSmooth adjustment | |

| Range of spindle speed | r/min | (L): 30-130(H): 65-260 | (L): 23-120(H): 65-258 |

| X/Z axis travel | mm | X:550 / Z:1250 | X:550 / Z:1250 |

| X/Z axis rapid traverse | mm/min | 4000 | 4000 |

| X axis motor speed | r/min | 1500 | 1500 |

| X axis motor torque | N.m | 18 | 18 |

| X axis motor power | Kw | 2.8 | 2.8 |

| Z axis motor speed | r/min | 1500 | 1500 |

| Z axis motor torque | N.m | 22 | 22 |

| Z axis motor power | Kw | 3.5 | 3.5 |

| Tailstock quill diameter | mm | 140 | 140 |

| Tailstock quill travel | mm | 300 | 300 |

| Tailstock quill taper | MT6 | MT6 | |

| Turret model | SLD170A04N | SLD170A04N | |

| Tool post type | Vertical 4- station | Vertical 4- station | |

| Turret dimension | mm | 300x300 | 300x300 |

| Turret indexing time | s | 5.6 | 5.6 |

| Chuck | K66-780 Four jaw chuck | K66-780 Four jaw chuck | |

| Positioning accuracy | mm | 0.02 | 0.02 |

| Repositioning accuracy | mm | 0.01 | 0.01 |

| Machine size | mm | 5000x2200x2100 | 5000x2200x2100 |

| Machine weight | Kg | 12000 | 14000 |

Standard configuration

1.CNC system :GSK,

2.The spindle servo speed,

3.three-jaw chuck;

4.Vertical four-position electric turret,

5.With tailstock;

6.Automatic lubrication system,

7.Turning cooling system.

Characters

Independent spindle, servo drives, variable speed.

1, We set up TRB (tapered rolling bearings) on this lathe to increase the rigidity of the spindle.

2, The spindle bore is very large and set up double chucks both front and back and you can choose electric chucks as you like.

3, The surface of the slide rail of the bed is treated by the super audio quench, which can be endurable and wear-resisting. The slide rail f saddle is treated by wear-resisting layer coated, to avoid the crawling.

4, There are two types of speed change: Manual and step less.

5, Set up self lubrication system, and easy to maintain.

Company Details

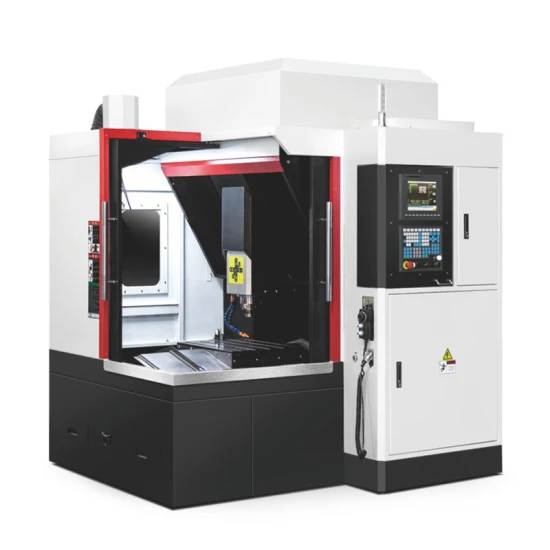

Prev: Szgh Vertical CNC Milling Machine and Machining Center Vmc650 High Precision

Next: Vmc1060 China Metal Working CNC Milling Machine Vertical Machining Center

Our Contact

Send now