Flat Bar Punching, Drilling and Shearing Machine for Steel Fabrication

Product Feature: In the production of metal structural parts, a large number of flat plate need to punch, drill and shea

Description

Basic Info.

| Model NO. | PDSL153-1305 |

| Power Source | Hydraulic Pressure |

| Precision | High Precision |

| Certification | GS, ISO 9001 |

| Condition | New |

| Transport Package | Plywood Case |

| Specification | 3200*3000*1900mm |

| Trademark | SUNRISE |

| Origin | China |

| HS Code | 8462411900 |

| Production Capacity | 200 Sets/Year |

Product Description

Product Feature:- In the production of metal structural parts, a large number of flat plate need to punch, drill and shear, this is a special machine to complete such jobs.

- The machine has an independent hydraulic power system and electrical numerical control system, using central centralized control.

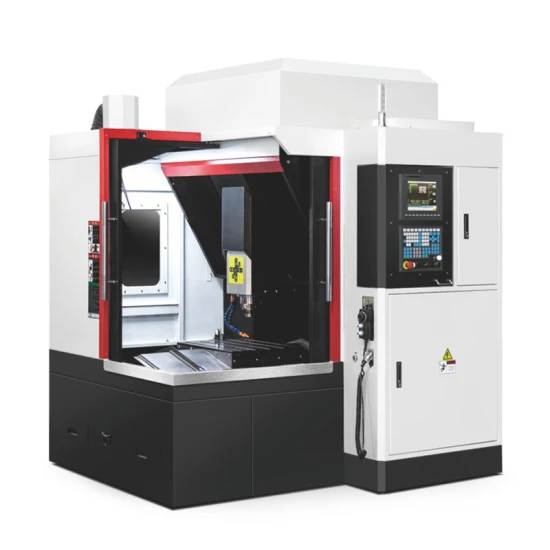

- The machine-frame is made by C-type plate welding, good rigidity, small volume, light weight, large operating space. The hydraulic system is based on the electromagnetic directional valve, supplemented by some cartridge components of the miniaturized system, simple structure, easy to use and maintenance.

- The machine has 3-axis CNC system, the workpiece can be precisely positioned at any position in the working area, and the function of punching, drilling and shearing can be completed. With origin positioning function. Ensure the machining accuracy of single workpiece and the interchangeability of the same workpiece.

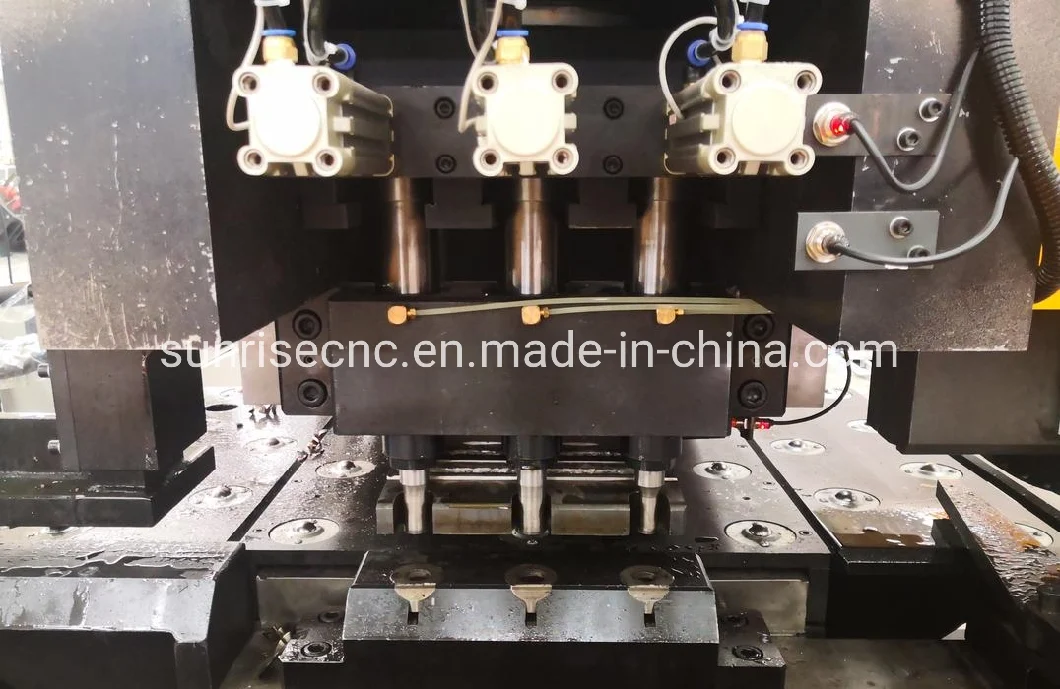

- The machine sets three punching die-stations and one drilling die-station The processing is multi - variety and multi - aperture. It is convenient to assemble and disassemble the mold, accurate to locate the mold, greatly shorten the working pause time and mold adjustment time, improve the working efficiency, and expand the scope of application of the machine.

- The shearing unit has independent pressing and holding device, closed frame structure, oblique edge shear, shear Angle is 3 degrees.

- Main hydraulic, air compressor and electrical components are imported, Details in the form down below.

- With fault self - diagnosis function

- The hydraulic system is mainly composed of oil tank, punching pressure regulating block, auxiliary control block 1, auxiliary control block 2, and master cylinder control block. Each part is connected by steel pipe or hose, under the control of electrical control system, drive each cylinder to complete clamping, positioning, pressing, punching and other actions. The tank is equipped with a vane pump to provide hydraulic power to the system.

- Reduce labor intensity of workers.

- More thoughtful spare parts with machine, always think of every detail for customers, check the spare part list down below.

Product Basic Parameter :

| Model | PDSL153-1305 | |

| Workpiece length range(mm) | 2500-13000 | |

| Workpiece width range(mm) | 100-500 | |

| Workpiece thickness range(mm) | 3-30 | |

| Max weight of workpiece(kg/m) | 447 | |

| Workpiece material(mm) | Q345 | |

| Punching unit | Punching force(KN) | 1500 |

| Punching die-stations(pcs.) | 3(2 small,1 big) | |

| Spacing of punching die stations(mm) | 75 | |

| Big die station Max diameter of punching hole(mm)×Plate thickness(mm) | Φ44.5×20 | |

| Small die station Max diameter of punching hole(mm)×Plate thickness(mm) | Φ30×20 | |

| Punching press material(pcs.) | 1 | |

| Drill unit | Qty. | 1 |

| Spindle taper | BT50 | |

| Max drilling dia (mm) | Φ50 | |

| Drilling depth(mm) | ≤30 | |

| Spindle rotating speed(r/min) | 30-3000 | |

| Spindle motor power(kW) | 22 | |

| Spindle feed stroke(mm) | 300 | |

| Distance from lower spindle face to work table(mm) | 100~400 | |

| Drilling pressure material(pcs.) | 1 | |

| Cutting unit | Shear force(KN) | 4300 |

| Cut mode | Oblique edge shear, shear Angle 3° | |

| Cutting pressure material(pcs) | 1 | |

| Cross conveyors | Prestore workpiece(pcs) | 3 |

| Loading quantity | Five pieces for one group | |

| Distance(mm) | 2000+2000+4000+4000 | |

| Power of Reducing(KW) | 2.2 | |

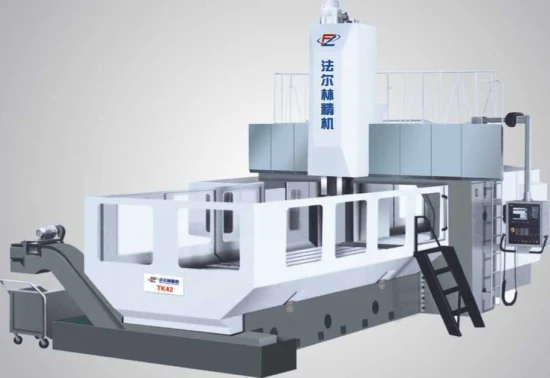

| Feed conveyor length(mm) | 13000 | |

| Outfeed conveyor length(mm) | 13000 | |

| X axis feeding mode | CNC trolley feeding | |

| X axis servo motor power(KW) | 4.4 | |

| X-axis effective stroke(mm) | 13000 | |

| X-axis positioning velocity(m/min) | 30 | |

| X axis drive mode | servo motor+gear rack | |

| Y axis servo motor power(KW) | 4.4 | |

| Y axis effective stroke(mm) | 500 | |

| Y axis positioning velocity(m/min) | 8 | |

| Y axis drive mode | servo motor+ ball screw | |

| Z-axis servo motor power(KW) | 2.9 | |

| Z axis effective stroke(mm) | 300 | |

| Z-axis positioning velocity(m/min) | 5 | |

| Z axis drive mode | servo motor+ball screw | |

| Hydraulic station | Motor power(KW) | 45 |

| High pressure(MPa) | 25 | |

| Low pressure(MPa) | 6 | |

| Number of the CNC axis | 3 | |

| Control mode | Mitsubishi PLC | |

| Programming method | Auto CAD or lofting software | |

| Data Import Function | DSTV,ASCII | |

| Nested functions | Possess | |

| Program function | Fault language display | |

| Working environment | Temperature :-10°~40°;Voltage:380V.50HZ, three phase;voltage range:±10% | |

| Total power(KW) | About 60 | |

| Total weight(t) | About 10 | |

| Overall dimension L×W×H(mm) | About 30000×3500×2200 | |

Our Contact

Send now