Heavy Duty Large Hole Horizontal Metal QK1363 CNC Pipe Thread Lathe Machine

Description

Basic Info.

| Model NO. | QK1363 |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Pipe threading range | 330-630 |

| Distance between centers | 1500/3000 |

| Max. load capacity | 10T |

| Guideway width | 1100 |

| Swing over bed | 1400 |

| Swing over cross slide | 800 |

| Name | Heavy Duty Large Hole Horizontal Metal QK1363 CNC |

| Transport Package | Plywood Case and Steel Set Below |

| Specification | size: 2100X2100X5000mm |

| Trademark | LUZHONG |

| Origin | China |

| Production Capacity | 50set/Month |

Packaging & Delivery

Package Size 570.00cm * 260.00cm * 260.00cm Package Gross Weight 18000.000kgProduct Description

Heavy Duty Large Hole Horizontal Metal QK1363 CNC Pipe Thread Lathe Machine Product Description

Big spindle bore and double chuck allows clamp and process big diameter pipes;

Integral machine bed adopts high strength iron to relize high rigidity and precision;

Ultrasonic frequency quenched guide-ways are hard enough for good wear-resistance;

Carriage and guide way contact surface pasted with Turcite B to maintain long-term accuracy.

Application:

CNC Heavy Duty Oil Pipe threading lathe machine is mainly designed to process all kinds of internal and external pipe threads including metric,inch,module,DP and taper threads,as well as having all the common functions of normal CNC lathe such as processing the inner bore and end face of shafts and disks.

This series lathe machine is widely used in industries including petroleum exploiting,coal and minerals mining,chemical piping and geological prospecting,it is high-efficiency equipment in processing and repairing drilling pipe,drilling rod,thread coupling and so on.

Standard Accessories:

Fanuc CNCsystem,NC turret 4 position,Coolant system,Lubrication system,Lighting system,Mobile

hand-wheel,Semi-shield,Manual tailstock,Chuck,Rear support bracket, Pad iron etc.

Optional Accessories:

CNC system(Simens,Fagor,GSK,KND),Turret(Servo,hydraulic,power),Chip conveyor,Air conditioner,Full-shield,Hydraulic tailstock,Chuck,Center rest,Follower rest,Signal light,Grinding attachment etc.

Product Parameters

Specification:

| SPECIFICATIONS | Units | QK1350 | QK1363 |

| Swing over bed | mm | 1200 | 1400 |

| Swing over cross slide | mm | 710 | 800 |

| Distance between centers | mm | 1500/3000 | 1500/3000 |

| Pipe threading range | mm | 330-510 | 330-630 |

| Guideway width | mm | 755 | 1100 |

| Max. load capacity | T | 6 | 10 |

| Spindle bore | mm | 520 | 640 |

| Spindle speed steps | - | 3 VF. 3 steps | 3 VF. 3 steps |

| Spindle speed range | rpm | 8-190 | 2-120 |

| Chuck | mm | 1000 4-jaw electric | 1250 4-jaw manual |

| Turret/tool post | - | 4Electric 4 position | |

| Tool shank size | mm | 50*50 | 50*50 |

| X axis travel | mm | 520 | 750 |

| Z axis travel | mm | 1250/2750 | 1250/2750 |

| X axis rapid traverse | mm/min | 4000 | 4000 |

| Z axis rapid traverse | mm/min | 4000 | 4000 |

| Tailstock quill diameter | mm | 160 | 220 |

| Tailstock quill taper | - | MT6 | Metric 80 |

| Tailstock quill travel | mm | 300 | 300 |

| Main motor power | kw | 22 | 37 |

| Coolant motor power | kw | 0.125 | 0.125 |

| Weight for 1500 | kg | 15000 | 18000 |

| Weight for 3000 | kg | 16000 | 19300 |

| Dimension for 1500 | mm | 5000*2300*2200 | 5600*2500*2500 |

| Dimension for 3000 | mm | 6500*2300*2200 | 7100*2500*2500 |

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you . 2: What's your main products of your company?

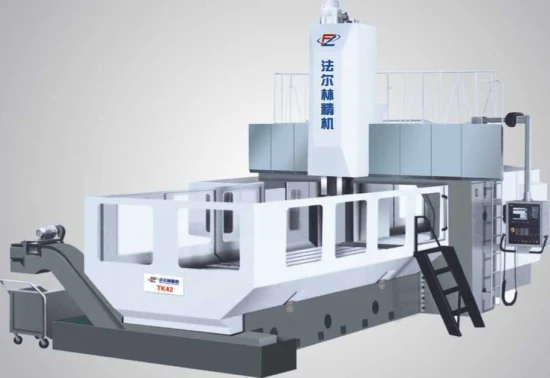

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on . 3: Where is our factory located? How can I visit there?A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us. 4. What is your trade terms?A : FOB, CFR and CIF all acceptable. 5: What's the Payment Terms ?A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight . 5: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

Prev: CNC Pipe Thread Cutting Machine Qk1319/Qk1320 /Qk1322CNC Oil Pipe Lathe

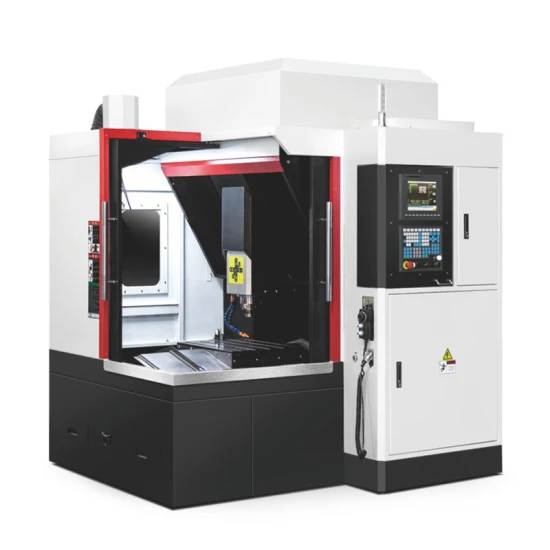

Next: Vmc 650 850 1050 1160 CNC Processing Machine Tool 3 4 5 Axis Vertical CNC Machining Center

Our Contact