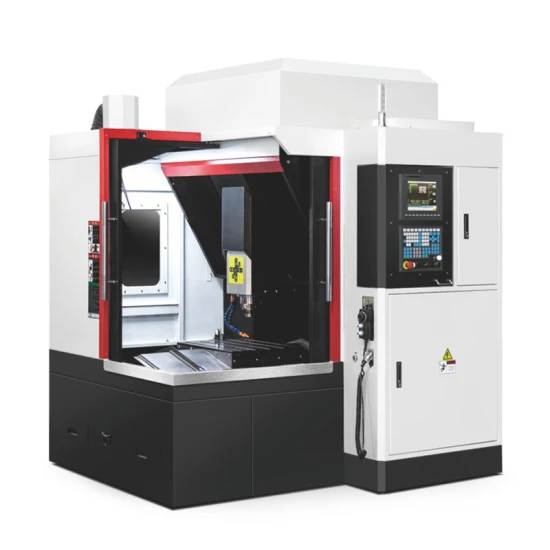

High Precision CNC Machine Center Vmc

Description

Basic Info.

| Model NO. | VMC-V85P |

| Performance Classification | High-End CNC Machine Tools |

| Certification | ISO 9001 |

| Condition | New |

| Spindle Type | Belt or Direct Spindle |

| Spindle | Short Nose Spindle |

| Spindle Power | 7.5kw |

| Distance Between Spindle and Nose | 120~670mm |

| Table Load | 600mm |

| T Slot | 5-18*100 |

| Minimum Set Moving Unit | 0.001mm |

| Three Axis Type | Linear Guide Way |

| X Axis Travel | 800mm |

| Spindle Taper | Bt40 |

| Z Axis Travel | 540mm |

| Y Axis Travel | 540mm |

| Machining | Mold and Parts Machining |

| Rotation Speed | 10000/12000/15000rpm |

| Table Size | 1000*550mm |

| Transport Package | Wooden Package |

| Specification | 2650*2900*2750mm |

| Trademark | JOINT |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 30 Sets |

Product Description

Fast speed and high efficiency create value

V85P with optimizing machine body structure design has advantages in processing efficiency, processing precision and smooth finish of mould curved surface processing, can be widely applied to 3C product, automatic special parts, electronic, mechanical, automobile, precision medicine and other field of product.

Features

1. Three axis is heavy duty and high rigidity roller linear way.2. X/Y axis width is 35mm, Z axis width is 45mm, it improves the cutting rigidity.3. Z axis increases the motor configuration, improves Z axis response.4. The reinforced design of the spindle box reduces virbration during spindle high speed operation and improves the heavy cutting capacity.5. For tapping efficiency, V85P has smaller tapping error.6. For composite curved surface, machining tool marks, quadrant points and gear marks are all within 0.005mm.7. With Fanuc MF(3) system s-grain and broach phenomenon are basically cleared.

Specification

| Model | V85P | |||

| Travel | X axis travel | mm | 800 | |

| Y axis travel | mm | 540 | ||

| Z axis travel | mm | 540 | ||

| Distance between spindle and table | mm | 120-670 | ||

| Distance between spindle and column | mm | 570 | ||

| Table | Size | mm | 1000*550 | |

| Load | kg | 600 | ||

| T slot size | mm | 5-18*100 | ||

| Spindle | Taper | BT40-140 short spindle nose | ||

| Install diameter | mm | 140 | ||

| Rotation speed | r/min | belt 10000/ direct 12000/direct 15000 | ||

| Output torque | Mitsubishi | N.M | NM35 | |

| Fanuc | N.M | 35.8 | ||

| Power | Mitsubishi | kw | 5.5 | |

| Fanuc | kw | 7.5 | ||

| Three axis | Maximum output torque | Mitsubishi | N.M | 13.7/13.7/22.5 |

| Fanuc | N.M | 11/11/20 | ||

| Power | Mitsubishi | kw | 2/2/3 | |

| Fanuc | kw | 1.8/1.8/3 | ||

| Cutting feed | m/min | 15 | ||

| Rapid feed | m/min | 36/36/36 | ||

| Arm type Tool magazine | Tool capacity | T | 24 | |

| Maximum diameter/ length/ weight of tool | mm/mm/kg | 80/200/8 | ||

| Maximum diameter of tool (no tool) | mm | 150 | ||

| Tool change time (T-T) | s | 2.8 | ||

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.006/0.006/0.006 | |

| Repeat positioning accuracy (X/Y/Z) | mm | 0.005/0.005/0.005 | ||

| Other | Dimension | mm | 2650*2900*2750 | |

| Power capacity | KVA | 15 | ||

| Weight | kg | 5500 | ||

Standard accessories:

1. Mitsubishi/ Fanuc controller system2. Fully enclosed cover3. Pneumatic system4. Anto lubrication system5. Work piece coolant system6. Heat exchange7. Air gun8. Water gun9. Spindle oil coolant10. 24T Arm type tool magazine11. Rear flishing12. Hand wheel13. RS232 Interface14. Alarming light15. Working light16. Guide way cover17. Technical documents18. Operation manual

Optional accessories:

1. Screw type conveyor2. Chain type conveyor3. Rotary table4. Coolant through spindle (CTS)

Machine body finite element analysis Extra wide base High rigid roller linear way

No heavy balance weight design Column big-span Reinforced spindle boc

Application Industry

Car front floor stiffener Mechanical parts

Hardware parts Automobile wheel hub machining

Next: CD46

Our Contact