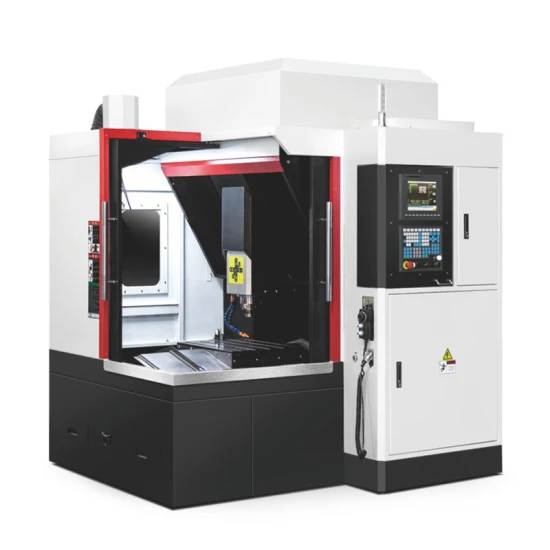

High Quality Metal Forming Power Presses for Progressive Stamping

High Quality Metal Forming Power Presses for Progressive Stamping 1.Application: Applicable to light, thin metal sheet f

Description

Basic Info.

| Power Source | Mechanical Drive |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Capacity(Tons) | 35 |

| Transport Package | Metal Pallet |

| Trademark | Goanwin |

| Origin | Ningbo, Zhejiang, China |

| HS Code | 8462991000 |

| Production Capacity | 1000PCS/Year |

Product Description

High Quality Metal Forming Power Presses for Progressive Stamping1.Application:

Applicable to light, thin metal sheet for single and progressive die application in blanking, piercing, bending, forming, can be connected with automatic feeding line.

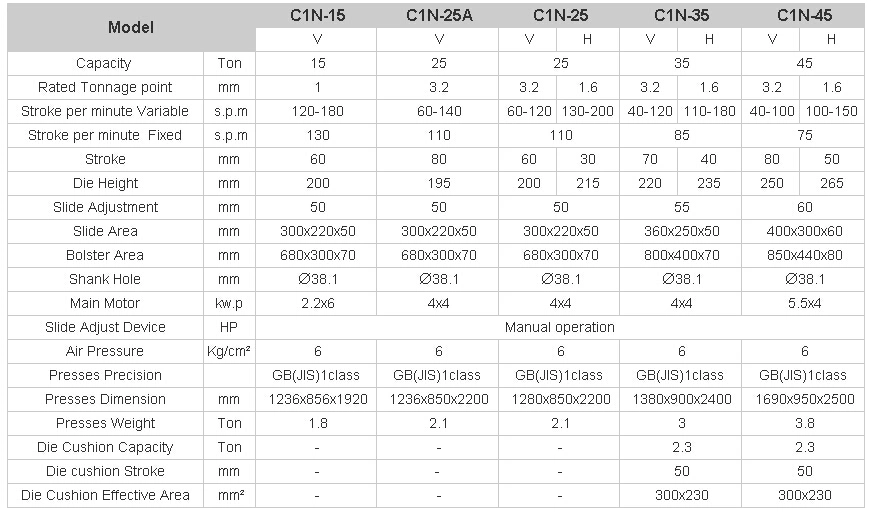

2.Press Tonnage: 15-400Ton

3.Press type: C-Frame Single crank mechanical press

4.Features:

•High rigidity steel frame

•Six-Point gibs for slide guide way

•Dry type clutch/brake

•Highly responsive hydraulic over-load protector(H.O.L.P.)

•Variable slide knock-out device

•Increased pressure point center distance enhances off-center load capability

Standard accessories:

Inverter

Touch pad

Preset counter

Electrical cam

Hydraulic over-load protector

Handle Slide adjust device(C1N below 60)

Electric Slide adjust device(C1N 60 or more)

Mechanical Die height indicatot(C1N below 60)

Electric Die height indicator(C1N 60 or more)

Balance device

Crank angle indicator

Electric stroke counter

Air source receptacle

Against over-run safety device

Misfeed detection consent

Power socket

Maintenance tool box

Operation Manual

Optional accessories:

Electrical automatic lubrication system

Pneumatic die cushion device

Foot switch

Quick die change device(die lifter, clamp and die arm sepjes)

Slide knock-out device

Die room light

Anti vibration press mount

Photo-electronic safety device

Feeder

Uncoiler

Leveler

Mechanism hand

After-sales Service:

1. Guaranty period

One year

2. Guaranty covers

Main parts of the machine, wearing parts not included

3. Parts delivery

Within 3working days by TNT

4. Technical support

Technical support via email or video, technicians available for overseas service with reasonable additional costs

5. Installation & commissioning

Seller can dispatch technicians to do installation & commissioning, technician costs will be on buyer's side

Contact:

Ms.Mindy

Prev: Beiene New Smart CNC Busbar Punching and Cutting/Shearing Machine

Next: Heavy CNC Milling Machine, CNC Machine Center, CNC Milling (EV850L)

Our Contact

Send now