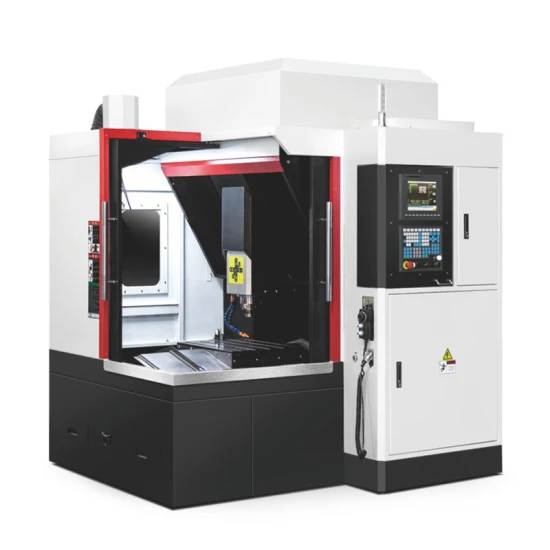

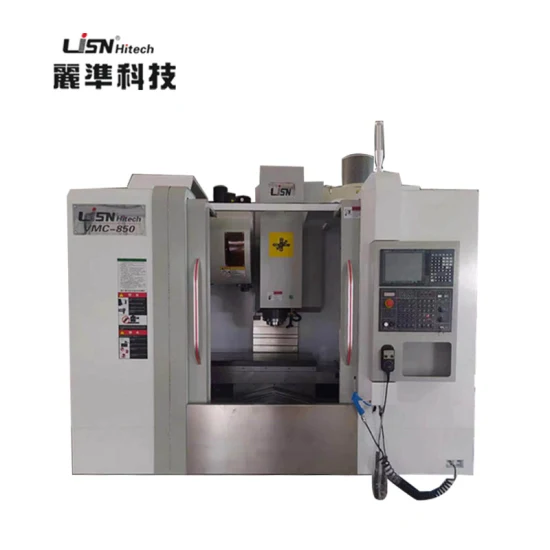

Vmc850 Multifunctional 4 Axis Lizhun CNC Vertical Milling Machine Center 12000rpm Fanuc/Mitsubishi/Siemens

Description

Basic Info.

| Model NO. | VMC-850 |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | SGS |

| Condition | New |

| Spindle Speed | 12000rpm |

| Spindle Hole Taper | Bt40 |

| X/Y/Z Axis Travel | 800/500/500 |

| Worktable Size | 1000X500mm |

| Transport Package | Wooden Box |

| Specification | 2495*1970*2360mm |

| Trademark | LiSN |

| Origin | China |

| HS Code | 8457101000 |

| Production Capacity | 10000pieces/Year |

Packaging & Delivery

Package Size 2490.00cm * 1970.00cm * 2360.00cm Package Gross Weight 5000.000kgProduct Description

Product DescriptionThe 4 axis VMC-850 is a high performance CNC vertical machining center developed and manufactured by our company. The machine has the characteristics of high rigidity, high speed and high precision and has more advantages on operation and capabilities compared with similar products. All castings of the machine have been secondary tempered to provide excellent rigidity and stability for the whole machine. This machine applied with high rigid C design on structure, it also has been done with reinforcement on machine ribs.All the contact faces have been scraped manually, which guarantees the durability of accuracy. X/Y axes apply with two types of rolling guide way: ball bearing and roller guide way, which is optional that customer can choose base on customer's needs. Z axis applies roller guide way, which enables the machine to be with high rigidity, low noise, and small friction. The machine equips with an air tank, and the water can be drained out manually. Spindle is connected directly, and the highest speed can reach 10000RPM, which make this machie as a good choice for machining some complex parts with high efficiency.

Main Features

- Mitsubishi M80 control system

- High speed and precision spindle

- Excellent chip flushing system

- Excellent structure design

- High rigidity of the whole machine

- Excellent worktable size: 500mm*1000mm

- Excellent load capability of worktable: 200kg

| ITEM | MODELS | VMC850 |

| WORKTABLE (WIDTH*LENGTH) | mm | 500x1000 |

| DISTANCE BETWEEN T SLOTS | mm | 5-18x100 |

| MAX LOAD BEARING OF WORKTABLE | kg | 600 |

| X/Y/Z AXIS TRAVEL | mm | 800/500/500 |

| DISTANCE FROM SPINDLE NOSE TOWORKBENCH | mm | 110-810/110-610 |

| SPINDLE HOLE TAPER | - | BT40 |

| SPINDLE SPEED RANGE | r/min | 12000 |

| SPINDLE MOTOR POWER | kW | 7.5 |

| X/Y/Z RAPID FEED SPEED | m/min | 36x36x36 |

| MAX CUTTING FEED SPEED | mm/min | 12000 |

| TOOLS MAGAZINE CAPACITY | pcs | 24 |

| X/Y/Z POSITION ACCURACY | mm | 0.005 |

| X/Y/Z RE-POSITION ACCURACY | mm | 0.003 |

| MACHINE DIMENSION | mm | 2495x1970x2360 |

| MACHINE WEIGHT | kg | 5000 |

Standard Configuration for VMC Series

1. Full Cover shield

2. Self-lubrication system

3. Working lights

4. Warning lights

5. Working condition warning lights

6. Self-powered electrical shutoff system

7. Clean air gun/ Water Tank / Transformer

8. Spindle air curtain and dust control system

9. 10000 RPM spindle

10.Worktable cleaning water gun

Optional Configuration for VMC Series

1. 24 disc manipulator tool magazine

2. Crawler chips remover

3. NC rotary table (4 Axis)

4. CTS

5. Tool detection system

6,. AJO

7. 12000 & 15000 RPM Direct connection spindle

8. Oil mist purifier

Company ProfileFAQ1. Is it all right to make customer's own brand name?

A: yes. we are available with OEM

2. Are you a manufactuer or trading company?

A:We are the manufacturer

3. Can you do the design for us?

A: yes. if you want a different control system design or higher column , we are available.

4 . What is your terms of delivery?

A: FOB shenzhen.

5. What's your payment term?

A: T/T OR L/C at sight.

Prev: J23

Our Contact