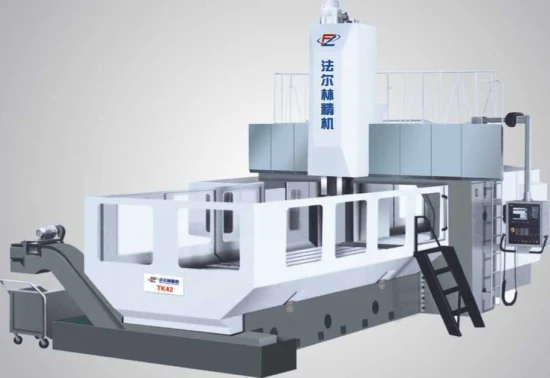

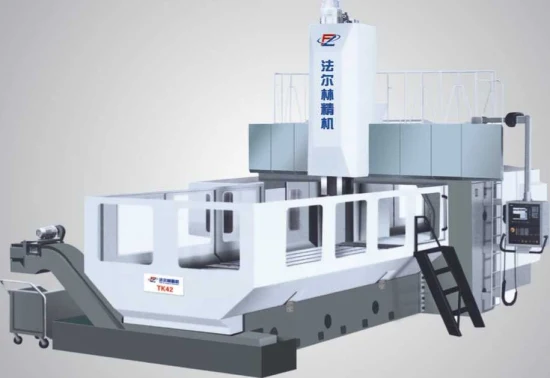

High Efficiency Fixed Beam Gantry CNC Milling Machine for Drilling Processes

Description

Basic Info.

| Model NO. | TK42 |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Condition | New |

| Grating | Spain Fagor or Heidenhain |

| Ball Screw | Germany Yifu or THK |

| Guide Rail Form | Square RAM Sliding Guide Rail |

| CNC System | Siemens-840DSL or Faunc |

| Spindle Taper | 50bt |

| Trademark | Faer Lin precision Machinery |

| Origin | Changzhou, China |

| Production Capacity | 500000 Pieces/Year |

Product Description

Product Description

Main characteristics of machine tool

TK42 series fixed beam gantry CNC milling machine for high-speed steel, carbide cutting tools, ferrous metals, nonferrous metals and some non-metal parts for roughing and finishing, can be a variety of board, disk type, box type , rack, pedestal, column and other high precision machining of large parts for CNC machining. After a workpiece clamping, automatic completion of milling, drilling, boring, reaming and tapping and other machining processes.The case of mounting accessories milling ram in the lower side, the workpiece can achieve five-sided machining.

The ram I is an all inclusive ram structure. The Z-axis guide rail pair adopts the sliding guide rail pair in the form of guide rail quenching and plastic pasting.The front bearing of the main shaft of the ram boring and milling head adopts group bearings, so that the main shaft has high precision, high load and low temperature rise. It can not only withstand large power and large torque cutting, but also has high precision and life of the main shaft.The drive motor and spindle motor of the three coordinate axes adopt imported AC servo motor and AC spindle motor Each coordinate axis is controlled in a semi closed loop by an encoder. According to the customer's requirements, grating can be used to achieve full closed loop control to improve the accuracy and accuracy retention of the machine tool.The machine tool can be configured with various accessory milling heads (optional by users) to realize five side machining.

Product Parameters

| Project | unit | TK4216 | TK4220 | TK4225 | TK4230 | ||||||

| Table size -width | mm | 1600 | 2000 | 2500 | 3000 | ||||||

| Table size -Length | mm | 3000 | 4000 6000 | 6000 8000 | 8000 10000 | ||||||

| CNC system | SIEMENS-840DSL or FAUNC | ||||||||||

| grating | Spain FAGOR or HEIDENHAIN | ||||||||||

| Width of gantry | mm | 2200 | 3200 | 3700 | 4200 | ||||||

| table stroke(X) | mm | 3500 | 4500 | 6500 | 6500 | 8500 | 8500 | 10500 | |||

| Travel of carriage on beam(Y) | mm | 2700 | 3200 | 4000 | 4000 | 4200 | 4400 | 4800 | |||

| Vertical stroke of spindle(Z) | mm | 1250 | 1250 | 1500 | 1500 | ||||||

| Square ram size | mm | 400x400 | 400x400 | 500x500 | 500x500 | ||||||

| Distance from spindle end face to workbench | mm | 250-1500 | 950-2200 | 750-2250 | 750-2450 | ||||||

| Main motor power | kW | 22/33 | 22/33 | 37/51 | 37/51 | ||||||

| Spindle speed | r/min | 20-2000 | 20-2000 | 10-2000 | 10-2000 | ||||||

| Maximum output torque of main shaft | Nm | 1000 | 1000 | 2000 | 2000 | ||||||

| spindle taper | BT | 50 | |||||||||

| Machine tool accuracy (with grating) | Positioning accuracy and repeated positioning accuracy | X/Y/Z-axis shall be implemented according to GB/T19362.1/2003 | |||||||||

| rapid traverse X | m/min | 8 | |||||||||

| rapid traverse Y | m/min | 8 | |||||||||

| Worktable bearing | Kg/m2 | 1500 | 2000 | ||||||||

| Guide rail form | Schneiberg or THK or HIWIN | ||||||||||

| Square ram sliding guide rail | |||||||||||

| Ball screw | Germany Yifu or THK | ||||||||||

| gas supply | MPa | 0.6 | |||||||||

| Machine weight | t | 52 | 55 | 82 | 110 | 135 | 160 | 180 | |||

Detailed Photos

Recommended products

Company Profile

1.General Information

Changzhou Faer Lin Precision Machine Co., Ltd. is located in Bingjiang economic development zone, new north district, Changzhou , Jiangsu, China. The whole plant area is 30006m2 with 15000m2 construction area.Our business grows dramatically during the past 5 years that the sales revenue develops from RMB 5 million in 2012 to RMB 50 millions around in 2016. The company was evaluated as Jiangsu high-technology enterprise in 2015, that we have 22 high-technology products and more than 20 patented technologies.Faer Lin is dedicated to build first-class technology developing system and train a expert team, in order to produce reliable automatic line and CNC special machine with high accuracy and high efficiency. 2.Company TeamOur shareholders and management team members are excellent talents from Jiangsu Duoleng CNC machine Co., Ltd.(Former was Changzhou General Machine Factory) who has more than ten years good experience in state-owned company management, product design, sales, R&D, manufacturing process and production. These excellent talents ensure we can have smooth and health development. Currently, we have 70 employees, 2 of them are certified with senior professional title, 21 with medium-grade professional title and 25 with junior professional title. It helps us to have capability to develop and manufacture first-class CNC machine and special machine.We run and manage the company according to joint-stock company requirement since it was founded. We have clear and reasonable organization, which make sure our company operate efficiently and smoothly.

Certifications

FAQ

1.MOQ1 set

2.DELIVERY TIME It depends on the machine and model you choose.All machines are 100% new and not used. 3.How can I choose the most suitable machines?Please tell me the machine type or parameter you are interested in, we can quote you the best price.You can also tell us the materials and size of the workpiece, or send us product pictures that you will process, we will choose the most suitable machine for you.4.Do you provide after-sales service?Of course. One-year warranty.5.Are you a factory or trading company ? We are a manufacturer factory 6.Why choose cooperate with us ? Reliable Quality and All components from world leading suppliers ;Cost-effective export infrastructure and total supply chain management ; 7.How does your factory do regarding quality control ? Reliable Quality is our dignity and we do quality checking carefully such as Incoming Quality Control, In Process Quality Control, Outgoing Quality Control , Environment Control, Product Traceabitity System , Internal Audits & Calibration, Equipment Control & Maintenance, Control of Non-Conforming Materials and etc.

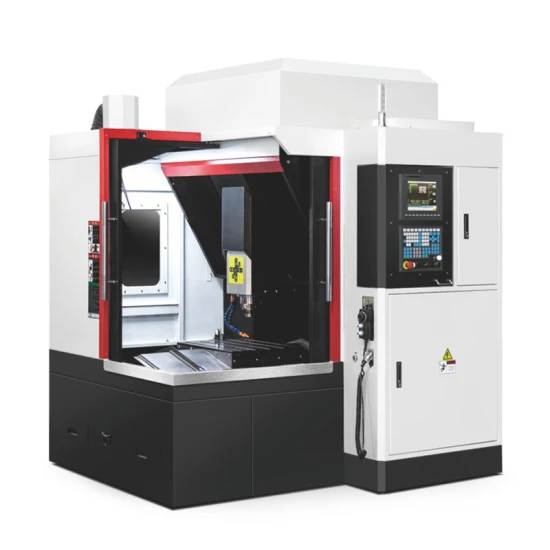

Prev: Fanuc Control Vertical CNC Drilling Tapping Milling Machine Center for Metal Vmc Cx

Next: 5 Axis Machine Center Vmc850 Vertical Milling Machine Taiwan CNC Machining Center

Our Contact